Every piece of jewelry has a story. Whether you received your first pair of diamond stud earrings for your 16th birthday, you were given a watch for graduation, or you received a family heirloom after a loved one passed away, jewelry has always been the traditional way to celebrate lifes' milestones. The best stories cross generations and involve turning old jewelry into new.

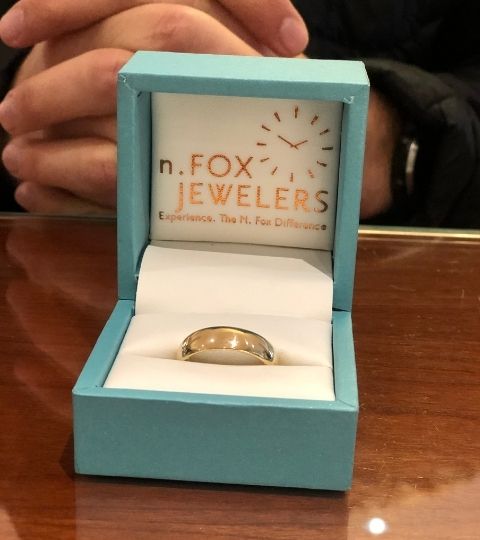

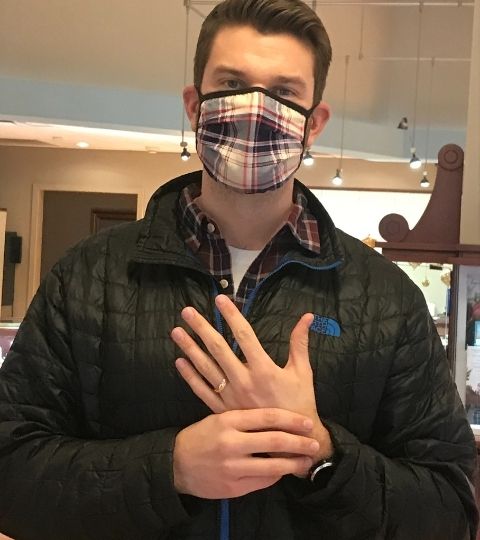

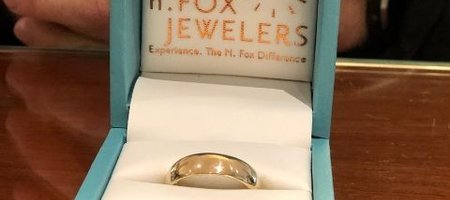

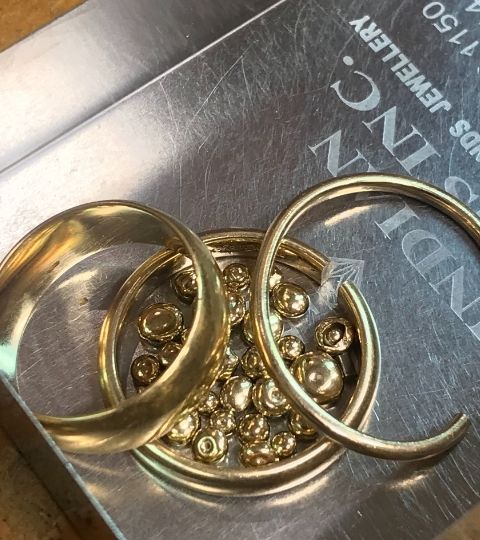

A recently engaged gentlemen, Matt, asked that N. Fox Jewelers, Custom Designer Grant Dorangrichia create a custom gold wedding band. This would all seem quite routine if the gold metal used in the production didn't come from the wedding rings of four of Matt's grandparents.

The gold elements are heated to approximately 1100 degrees celsius. Once the gold reaches a molten state and is flowing as one mass it can be poured into a casting mold to form an ingot and cool. The gold ingot is then passed through a series of decreasing rolling mills to form what will become the custom solid gold wedding band. With every few passes our Custom Jewelry Designer, Grant must heat the gold ingot until it is red hot, then allowed to cool down slowly. This is called annealing and helps to prevent the metal becoming too brittle to work with.

When the ingot is the required width and depth for the style of the wedding band it is bent to form a circle with the use of a forming press. Matt requested a straight polished finish. To achieve this, we emery with progressively finer grades and follow with buffing and polish. The end result is a breathtaking reminder of love's past and future.